Ambionse Insulated Concrete Forms (ICF): Strong, Efficient, and Durable Walls for Residential Homes

Ambionse Insulated Concrete Forms (ICF) offer a superior solution for creating robust, long-lasting exterior walls. Designed for residential applications, Ambionse provides energy-efficient insulation (R 3.0), acoustic quietness, and an impressive fire rating of up to 4 hours.

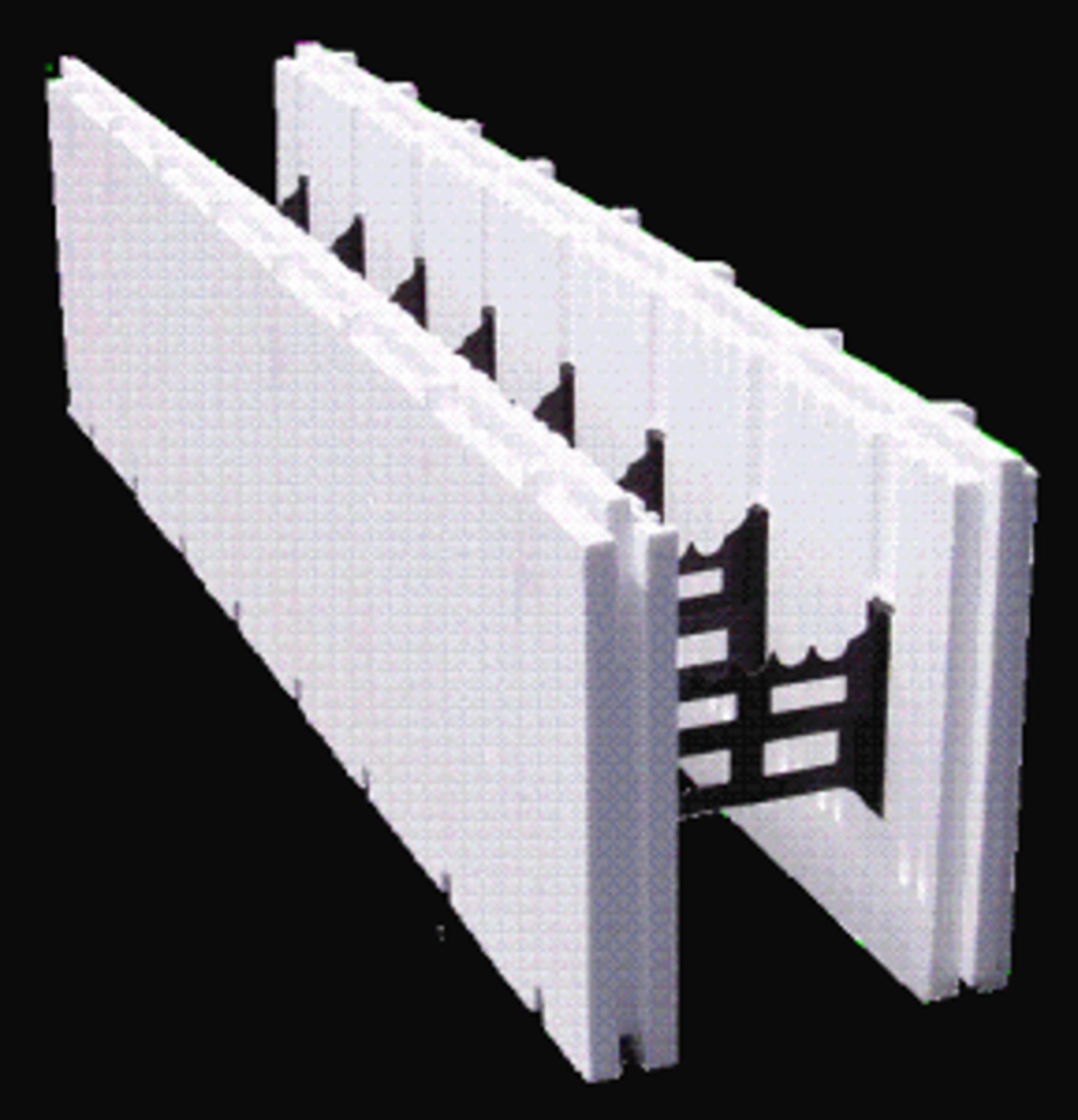

Innovative Design

Ambionse Polyblock walls are constructed using two exterior polystyrene (EPS) panels, spaced apart by durable plastic bridges. The inner cavity is reinforced with both horizontal and vertical steel, ready for concrete pouring to create a solid and stable wall.

Seamless Construction Process

With a skilled builder, Ambionse Polyblocks can be easily assembled, while an engineer will specify the appropriate type and amount of reinforcing steel to suit your project’s requirements.

Ambionse – Polyblock Sizing

- 190 Series Blocks: 1200mm (L) x 300mm (H) x 190mm (W)

- 250 Series Blocks: 1200mm (L) x 300mm (H) x 250mm (W)

- 300 Series Blocks: 1200mm (L) x 300mm (H) x 300mm (W)

- Corner blocks available for 190 and 250 series

Why Choose Ambionse Polyblocks?

- No wood, no rot: Ensures durability and longevity.

- Stable reinforced concrete core: Offers unmatched structural integrity.

- Continuous insulation (R 3.0): Keeps interiors comfortable year-round.

- Quiet interiors (STC 53 for 250 series): Reduces noise for a peaceful home.

- Energy-efficient design: Lowers heating and cooling costs.

- Long lifespan: Built to last over 50 years.

- Airtight walls: Improves energy efficiency and reduces drafts.

Versatile Applications

Ambionse Polyblocks are ideal for a wide range of projects, including:

- Residential housing walls

- Commercial construction walls

- Apartment walls

- Foundation walls and footings

- Retaining walls

- Basement walls

- Intertenancy walls

- Swimming pool walls

- Fencing and landscaping walls

- Garden edging

Design and Build with Ambionse

Collaborate with your preferred architect or architectural designer to create a home that incorporates the strength and efficiency of Ambionse. If you need assistance finding a builder, we’re happy to recommend trusted professionals.

Choose Ambionse for your next project—where strength meets innovation.

Technical Resources

Key Tips for Ambionse ICF Construction

1. Plan Ahead

Determine exact sizes and placements for openings (windows, doors, vents) before starting.

2. Prepare the Footing

Ensure the footing is level for a straight wall. Use wedges if necessary.

3. Drainage and Elevation

Inspect drain tiles or Form-A-Drain. Confirm elevations for the basement, footings, garage floor, and main floor.

4. Pre-Build Components

Pre-cut and bend rebar, and pre-build window formwork for efficiency.

5. Layout and Measurements

Snap lines on the footings and lay out the first two rows of blocks. Check for square and adjust as needed.

6. Cutting and Assembly

Measure and cut blocks carefully using a square and tape measure. Use power tools like a table saw for precision.

7. Corners and Braces

Frequently check corners for level. Allow for slight settling when installing braces and avoid overtightening.

8. Minimize Waste

Use short pieces of block in the second-to-last row, ensuring ties line up.

9. Pre-Pour Checklist

Ensure all braces and corners are secure. Keep the jobsite clean and ready for pouring.

10. Concrete Pouring

Use a pump truck to pour at a 120-150mm slump. Vibrate concrete by “rodding” and pay extra attention to openings.

11. During the Pour

Watch for blowouts and have tools ready to fix any issues. Adjust braces as needed to maintain level walls.

12. Post-Pour Care

Level the top of the wall, clean overspill, and ensure anchors and rebar are in place. Braces can be removed the next day, but avoid backfilling until the wall has fully cured.

1. What makes Ambionse walls energy-efficient?

Ambionse walls achieve energy efficiency through their high R-value of 3.0, which minimizes heat loss and provides consistent indoor temperatures.

2. Are Ambionse walls environmentally friendly?

Yes, Ambionse uses polystyrene, which is recyclable, and the system’s energy efficiency helps reduce overall carbon footprints.

3. Can Ambionse walls be painted or finished directly?

Yes, Ambionse walls can be finished with plaster, paint, or other surface treatments, providing a smooth and durable aesthetic.

4. How long does it take to construct a building with Ambionse?

The construction time varies based on the project size but is typically faster than traditional construction methods due to the lightweight and modular nature of the system.

5. What types of concrete can be used with Ambionse?

Ambionse walls require standard concrete with appropriate strength and slump as specified in the technical guide for optimal performance.

6. Is special equipment required to install Ambionse walls?

No special equipment is required; standard construction tools and proper bracing are sufficient for installation.

7. Can Ambionse be used in earthquake-prone areas?

Yes, Ambionse walls are engineered to provide excellent structural integrity, making them suitable for earthquake-prone regions.

8. What is the maximum height that Ambionse walls can be built?

The maximum height depends on the design and structural requirements of the project. Consult Styrobeck’s technical team for specific guidelines.

9. How do Ambionse walls perform in terms of soundproofing?

Ambionse walls provide excellent acoustic insulation, significantly reducing noise transmission between rooms or from external sources.

10. Is training required to use the Ambionse system?

While the system is designed to be user-friendly, training or guidance from Styrobeck’s team is recommended for first-time users to ensure optimal results.

11. Can electrical and plumbing systems be integrated into Ambionse walls?

Yes, Ambionse walls can accommodate electrical conduits and plumbing systems by carving channels into the polystyrene blocks before concrete pouring.

12. How durable are Ambionse walls?

The combination of reinforced concrete and polystyrene formwork creates a highly durable wall system that withstands weather, wear, and time.

13. Are there specific maintenance requirements for Ambionse walls?

Ambionse walls require minimal maintenance. Regular inspections and timely repairs of finishes or coatings will ensure longevity.

14. What kind of warranty does Styrobeck offer for Ambionse?

Styrobeck offers warranties on the materials used, with terms depending on the project and location. Contact Styrobeck for detailed warranty information.

15. Can Ambionse be used for multi-story buildings?

Yes, Ambionse is suitable for multi-story construction. Proper structural engineering and design considerations must be adhered to.

16. Are Ambionse walls resistant to pests?

Yes, the polystyrene used in Ambionse is resistant to termites and other pests, making it a reliable choice for long-term use.

17. What is the fire rating of Ambionse walls?

Ambionse walls can achieve a fire rating of up to 4 hours, depending on the wall thickness and project specifications.

18. Are Ambionse walls waterproof?

While the concrete core is inherently water-resistant, additional waterproofing measures may be needed for specific applications like basements or wet areas.

19. How does Ambionse compare to traditional construction methods?

Ambionse offers faster construction, improved energy efficiency, and enhanced acoustic performance compared to traditional brick or block systems.

20. Where can I find technical support for Ambionse?

Styrobeck provides comprehensive technical support, including design advice and on-site assistance. Visit their website or contact their team for details.